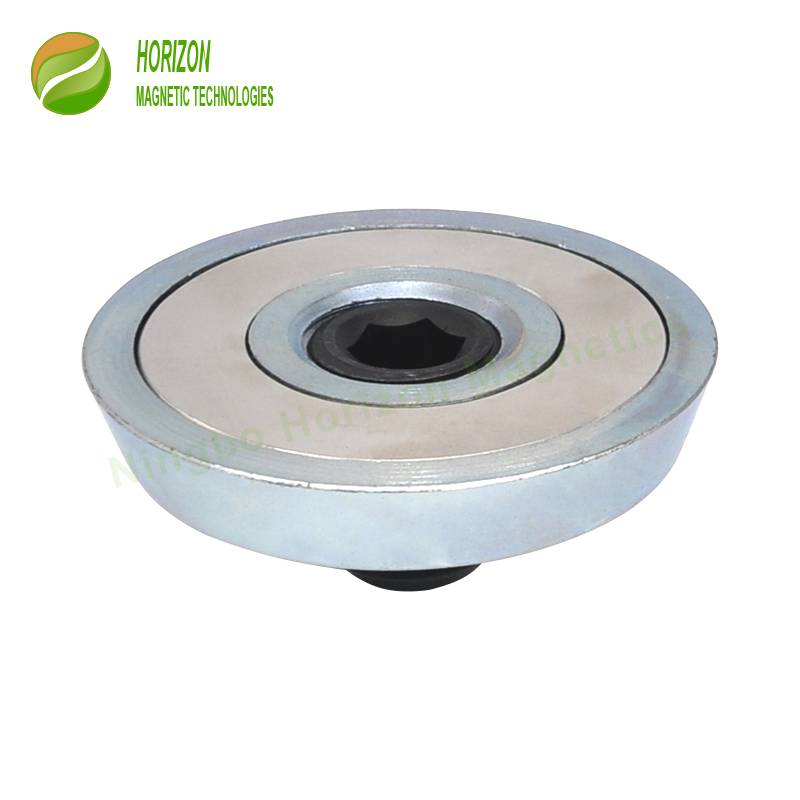

Chimodzimodzinso ndiNeodymium pot maginito, maginito oyikapo amakhala ndi mphete ya NdFeB maginito, casing chitsulo ndi ndodo ya ulusi. Chitsulo chachitsulo chimateteza maginito a Neodymium kuti asawonongeke kunja ndikuyika mphamvu ya maginito yazitsulo zotsekedwa.Neodymium mphete maginitokumtunda wolumikizidwa kokha kuti apange mphamvu yayikulu kwambiri kuposa maginito a Neodymium osiyana. Komabe ili ndi mfundo zina zosiyana ndi maginito a mphika kuti ikwaniritse zofunikira zogwiritsira ntchito mu precast konkire. Mawonekedwe a chitsulo chosungiramo chitsulo amawongoleredwa ndipo ndodo ya ulusi imasinthasintha kuti maginito olowetsamo azikhala osavuta kuchoka ku konkire yowumitsidwa kudzera pa wrench ya socket.

1. Zida: Neodymium maginito ndi ntchito mkulu ndi kalasi + Zitsulo casing ndi ndodo

2. zokutira: Maginito wokutidwa ndi NiCuNi kapena Zinc + chitsulo chotchinga ndi Zinc kapena Copper

3. Kukula ndi mphamvu: Ponena za Data Data

4. Phukusi: Adzalongedza m’makatoni a malata. Makatoni odzazidwa mu mphasa kapena chikwama chambiri

1. Mphamvu ya maginito ndi mapangidwe apadera ndi mapangidwe amathandizira kuwala komanso kosavuta kugwira ntchito.

2. Ndizogwiritsidwanso ntchito komanso zolimba kupulumutsa ndalama zomwe zimagawidwa nthawi yayitali.

3. Ndiwofulumira kuyika ndikuwongolera bwino komanso mtengo wake.

4. Ikhoza kusintha khalidwe la precast konkire zinthu.

5. Mphamvu ya maginito ndi yokwanira kuti ikhazikitse ndikumangiriza zigawo zomwe zili mkati molondola panthawi yoponyera konkire kapena kugwedezeka kuti athe kunyamula otetezeka.

1. Kudziwa kosagonjetseka mu Neodymium maginito, chinthu chofunikira kwambiri kuti mutsimikizire kuyika kwa maginito

2. Kudziwa maginito ndi kupanga m'nyumba kuthandiza makasitomala kuzindikira zinthu zamakasitomala kuyambira pamalingaliro mpaka kuzinthu zomaliza zamaginito

3. Masitayilo ndi makulidwe ambiri omwe alipo kuti apulumutse mtengo wa zida ndi mtengo wazogulitsa kwa makasitomala

4. Miyeso yokhazikika yomwe ilipo ndipo imapezeka kuti iperekedwe mwamsanga

5. Complete kotunga precast konkire maginito kuphatikizapokutseka maginito, maginito chamfers ndi zopangidwa mwamakonda zopangidwa maginito kukumana ndi kugula kamodzi kwamakasitomala

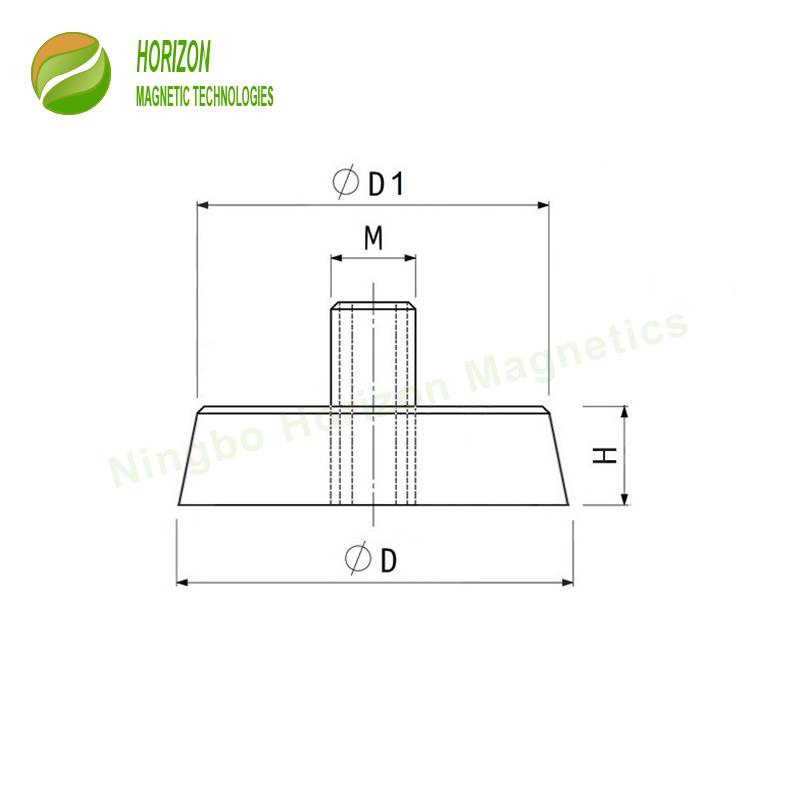

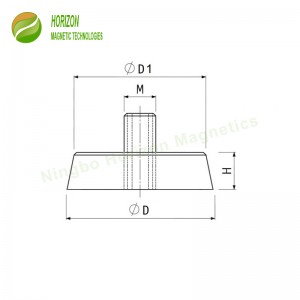

| Gawo Nambala | D | D1 | H | M | Kutentha Kwambiri Kwambiri | |

| mm | mm | mm | mm | °C | °F | |

| HM-IN45-M8 | 45 | 40 | 8 | 8 | 80 | 176 |

| HM-IN45-M10 | 45 | 40 | 8 | 10 | 80 | 176 |

| Chithunzi cha HM-IN54-M12 | 54 | 48 | 10 | 12 | 80 | 176 |

| HM-IN54-M16 | 54 | 48 | 10 | 16 | 80 | 176 |

| HM-IN60-M20 | 60 | 54 | 10 | 20 | 80 | 176 |

| HM-IN77-M24 | 77 | 73 | 12 | 24 | 80 | 176 |

1. Pewani kuphimba pamwamba pa maginito a Neodymium kuti musunge mphamvu ya maginito.

2. Gwiritsani ntchito kapena sungani maginito oyika pansi pa 80 ℃. Kutentha kwakukulu kungapangitse maginito kuchepetsa kapena kutaya mphamvu ya maginito.

3. Ndikofunikira kwambiri kuti magolovesi azivala kuti ateteze manja a ogwira ntchito kuti asatsine. Chonde sungani kutali ndi zida zamagetsi ndi zitsulo zosafunikira za ferromagnetic. Chenjezo lapadera liyenera kuchitidwa ngati wina wavala pacemaker, chifukwa mphamvu ya maginito imatha kuwononga zamagetsi mkati mwa makina othamanga.